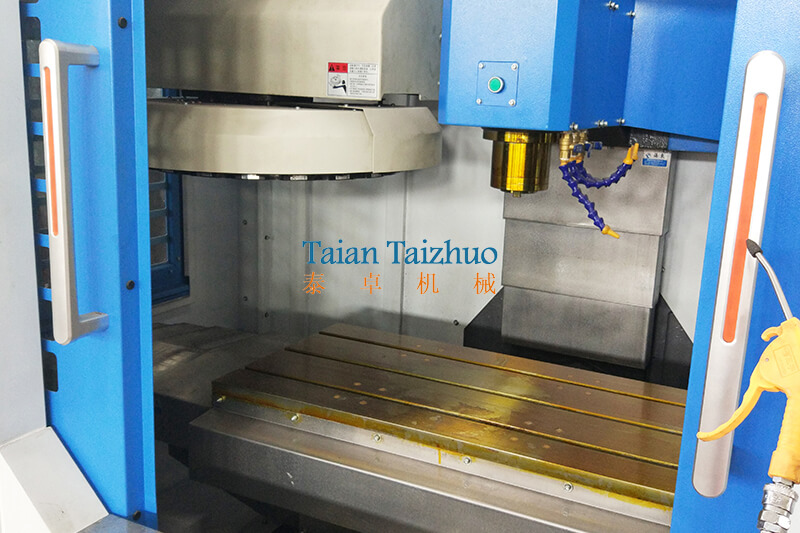

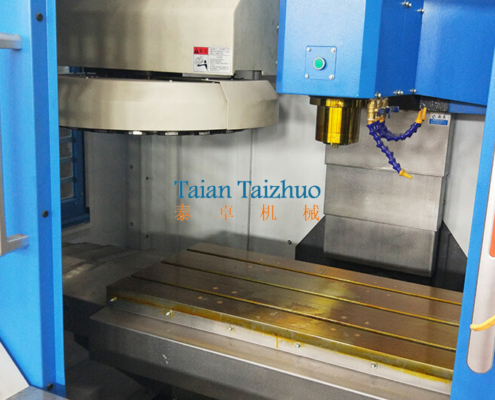

CNC Machining Center Datasheet

Item |

VMC1060 |

|

Travel |

X axis |

1000mm |

Y axis |

600mm |

|

Z axis |

600mm |

|

Spindle nose to table |

150-750mm |

|

Spindle nose to column |

600mm |

|

Feed |

Max. X rapid feed |

24m/min |

Max. Y rapid feed |

24m/min |

|

Max. Z rapid feed |

18m/min |

|

Cutting feed |

1-10000mm/min |

|

Torque |

15/15/15N.m |

|

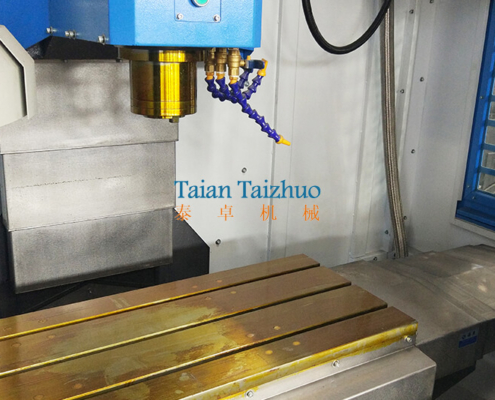

Table |

Table size |

1200x600mm |

Max. load |

800kg |

|

T slot |

5-18-100mm |

|

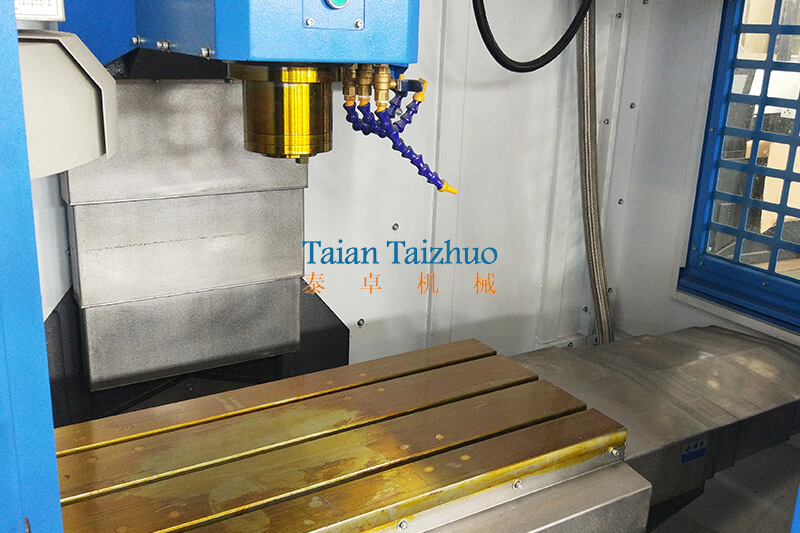

Spindle |

Type |

Belt |

Speed |

50-8000rpm |

|

Spindle bore |

150mm |

|

Spindle taper |

BT40 |

|

Pull stud |

MAS403-40BT-1 |

|

Spindle motor synchronizing wheel |

Taiwan |

|

Spindle belt |

Taiwan |

|

Main motor |

11/15kw |

|

Acuracy |

Positioning Accuracy (JIS) |

±0.015/300mm |

Repeatibility (JIS) |

±0.0075mm |

|

Machine |

Size |

3000×2500×2650mm |

Weight |

6000kg |

|

Standard configuration:

1. KND1000 CNC Controller.

2. Taiwan BT40-150-8000 spindle.

3. Taiwan Funnel Type Tool Changer.

4. Taiwan Hiwin Roller Linear Guideway.

5. Taiwan Hiwin Ball Screw.

6. Automatic Central Lubrication System.

7. Work Lamp.

8. Full Enclosure Machine Guard.

Optional Configurations:

1. GSK KND Siemens Fanuc Mitusbishi GUNT.

2. Arm type tool changer.

3. Automatic chip conveyor.

4. 4th axis and 5th axis.

5. Spindle oil coolant, Center to water.

6. Renishaw probe for workpiece and tool.

7. Spindle direct connection.

CNC Machining Center VMC1270 (1)

CNC Machining Center VMC1270 (1) CNC Machining Center VMC850 (5)

CNC Machining Center VMC850 (5) CNC Machining Center VMC650 (3)

CNC Machining Center VMC650 (3) CNC Machining Center VMC500 (1)

CNC Machining Center VMC500 (1) CNC Machining Center VMC850 (5)

CNC Machining Center VMC850 (5) CNC Machining Center VMC1270 (1)

CNC Machining Center VMC1270 (1)