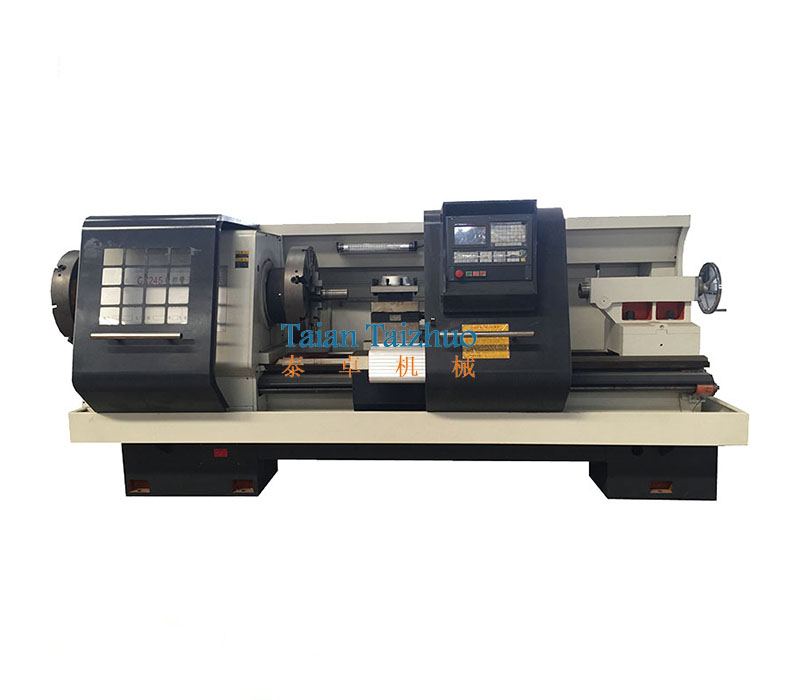

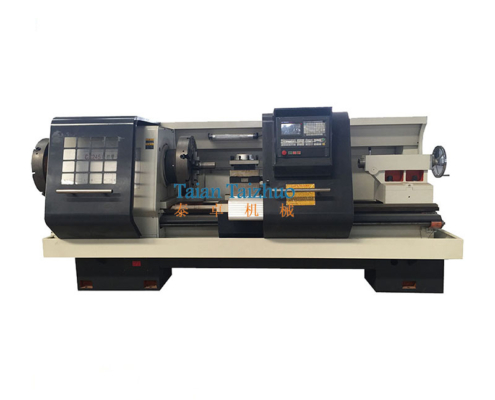

Pipe Threading Lathe Machine Datasheet

Item |

CK245 |

Distance between two thimbles |

1000mm |

Max. swing over bed |

800mm |

Spindle through hole diameter |

250mm |

Machining pipe outside diameter range |

50-245mm |

Guide width |

600mm |

Max. rotation diameter over pallet |

560mm |

Spindle servo speed |

20-400r/min |

Servo motor power/frequency |

11kw/33.3Hz |

Chuck diameter/bore |

Φ630/Φ250mm |

Big hole three jaw chuck |

K11-Φ630D |

Distance between two chuck ends |

1580mm |

Range of inch threads |

0.1-254 |

Range of metric threads |

0.1-400 |

Maximum stroke/machining length |

1000mm |

Fast moving speed |

4-6 m/min |

Minimum setting unit |

0.001mm |

Repeat positioning accuracy |

0.025mm |

Maximum stroke |

480mm |

Fast moving speed |

3-5 m/min |

Minimum setting unit |

0.001mm |

Repeat positioning accuracy |

0.016mm |

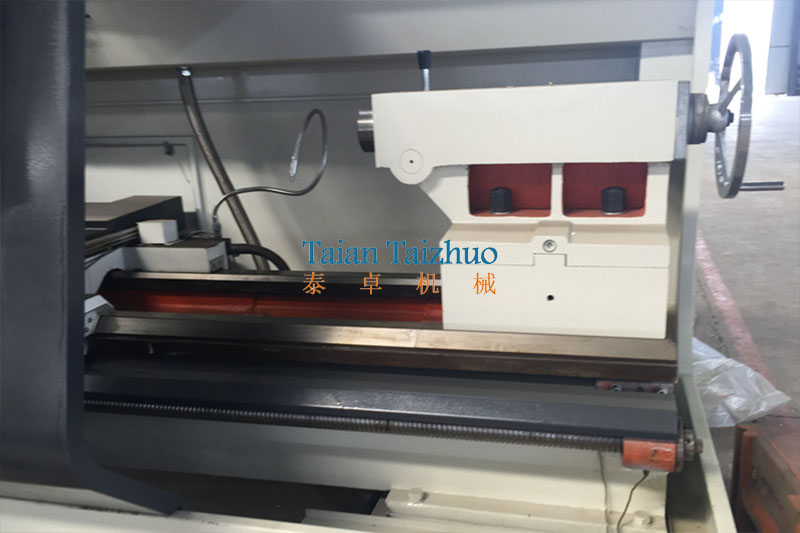

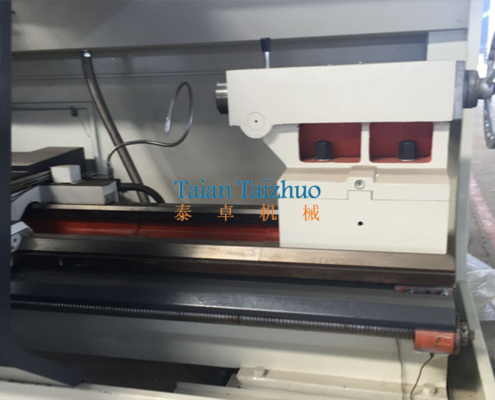

Tailstock sleeve diameter |

Φ100mm |

Tailstock sleeve taper hole |

MT5 |

Tailstock quill stroke |

250mm |

Section of turning tool |

40x40mm |

Electric tool carrier |

Four-station SLD170A04N280x280mm |

Machine size |

4000x2300x2200mm |

Gross weight/Net weight |

6/5.8 |

Standard Configuration:

1) CNC system: GSK980TC3.

2) Front and rear four-jaw manual chuck.

3) Vertical four-station electric turret.

4) With tailstock.

5) Automatic lubrication system.

6) Turning cooling system.

7) The rear bracket.

8) Voltage:380v 50hz 3phases.

Pipe Threading Universal Lathe Machine Q245 (3)

Pipe Threading Universal Lathe Machine Q245 (3) Pipe Threading Universal Lathe Machine Q1322 3

Pipe Threading Universal Lathe Machine Q1322 3 Pipe Threading CNC Lathe Machine CK350 (3)

Pipe Threading CNC Lathe Machine CK350 (3) Pipe Threading CNC Lathe Machine CK1322 (2)

Pipe Threading CNC Lathe Machine CK1322 (2) Pipe Threading CNC Lathe Machine CK1322 (2)

Pipe Threading CNC Lathe Machine CK1322 (2) Pipe Threading CNC Lathe Machine CK350 (3)

Pipe Threading CNC Lathe Machine CK350 (3)